Abrasive Blasting Equipment

All of Applied Blast Machines are manufactured in Ireland, are CE Approved supplied with:

- 10 Metres of Heavy Duty Blast Hose

- Tungsten Carbide Nozzle

- 10 Meters of Air Supply Hose

- Pneumatic Remote Control System with Remote Dead Man’s Handle

- 12 Month Warranty

CHECK OUT THESE VIDEOS TO FIND OUT WHAT MAKES APPLIED BLASTING MACHINES THE BEST ON THE MARKET

Our Sandblasting Models

Applied 20 Litre Blast Machine

- Smallest in our range

- Highly efficient blast pot with great mobility

- Ideal for small blasting work

- Remedial work – glass etching and general maintenance

Applied 40 Litre Blast Machine

- High performance, versatile blasting machine

- Good manoeuverability and improved blasting time

- Ideal for small to medium sized projects

- Continuous blast time of approx 20 mins

Applied 100 Litre Blast Machine

- Popular with those involved in medium sized projects

- Continuous blast time of approx 40 mins

- Fabricated from heavy gauge steel

- This blast pot is of the highest quality available

Applied 140 Litre Blast Machine

- Ideal machine for medium to larger projects

- Refurbishment work where mobility and high production rates are important

- Continuous blast time of approx 55 mins

- Fabricated from heavy gauge steel this blast pot is of the highest quality

Applied 200 Litre Blast Machine

- Largest in our range

- Highly efficient

- Blast pot is ideal for larger sandblasting contractors

- Blasting in shipyards and for fabrication industries

- Continuous blast time of approx 80 mins

See what makes up an Applied Sand Blasting Machine

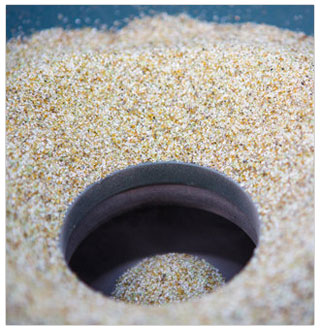

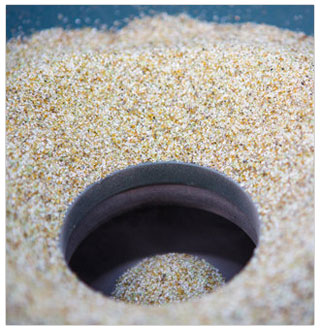

Concave top for rapid filling of pot which is sealed automatically by a heavy duty popup valve.

Lifting eye

Compact remote control system and silencer. This gives the operator full control at the end of the blast hose, giving higher efficiency of abrasive, increased performance and operator safety.

Exhaust muffler greatly reduces bleed off noise

Moisture water separator. Assists in removing the water and moisture from the incoming compressed air supply to the blast pot, this helping to ensure that the abrasive does not become damp.

Quick Claw Coupling

Flexible pusher line guarantees air flow without pressure loss caused by elbows, and eases valve replacement.

Fitted with abrasive control valve

Heavy Duty Wheels

Large inspection hole for easy access to inside

Pressure gauge and relief valve

Concave top for rapid filling of pot which is sealed automatically by a heavy duty popup valve.

Lifting eye.

Exhaust muffler greatly reduces bleed off noise.

Moisture water separator. Assists in removing the water and moisture from the incoming compressed air supply to the blast pot, this helping to ensure that the abrasive does not become damp.

Quick Claw Coupling.

Flexible pusher line guarantees air flow without pressure loss caused by elbows, and eases valve replacement.

Fitted with abrasive control valve.

Heavy Duty Wheels.

Large inspection hole for easy access to inside.

Pressure gauge and relief valve.